New Accelerator to Focus on Hardware Startups

Given the exponential growth we've seen in mobile app development, it makes sense that most people associate venture accelerator programs with software startups. But plenty of new ideas require hardware -- whether it's the smartphone needed to run those trendy apps, or the glorious future analysts see in the "internet of things."

But if the next big thing is a connected thermostat, a fancy light bulb, or a smart kitchen appliance, someone is going to have to design, prototype, and finally manufacture it. And compared to software, hardware is hard. So as more entrepreneurs go into business with a maker mindset, there's now a growing movement to establish hardware accelerator programs. There were at least 50 in operation worldwide last year, and soon Hawaii will be home to one more.

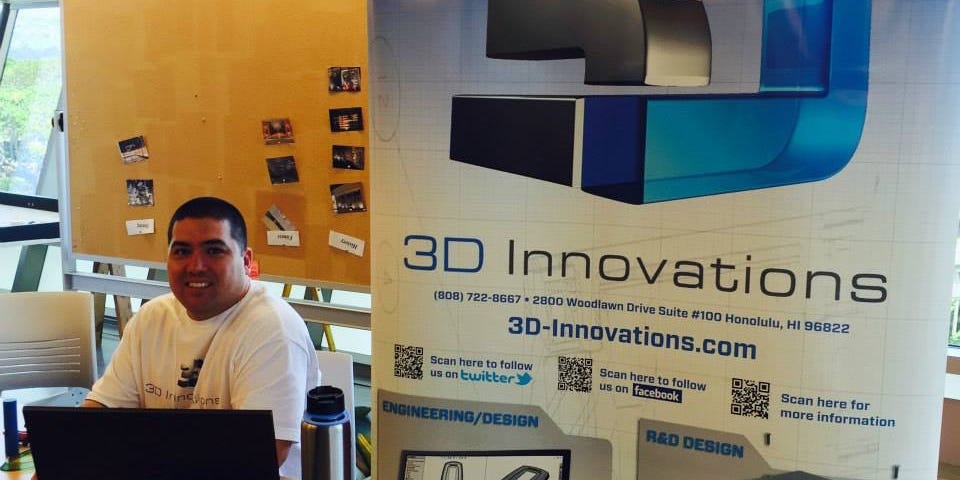

Startup Connector is a Honolulu-based manufacturing accelerator announced last week. The accelerator was co-founded by long-time local 3-D printing expert Collin Kobayashi of 3D Innovations and former Kai Sensors CEO Bob Nakata.

"Our main objective is to work with hardware development companies, to get them ready for full scale manufacturing," Kobayashi said on last night's Bytemarks Cafe. "Getting them through the whol product development cycle, beyond prototyping to mass production."

Startup Connector will further diversify Hawaii's growing community of accelerator programs, which already includes Blue Startups, XLR8UH, the Energy Excelerator and the GVS Accelerator -- not to mention an even wider array of investment funds. Of course, many of these existing programs have hatched hardware plays, but Startup Connector will focus on helping manufacturing companies get off the ground.

"What we've seen is that there are a lot of products being developed, and there's different points where the companies get off track -- whether it's not having the right technical expertise, or not having the right experience, or not knowing where to go," Kobayashi said. "The main gap that I've seen is that these companies can get through testing and prototyping, but really get stuck on getting their data package ready for full-scale production."

He added that one of the biggest pitfalls manufacturing startups run into are testing and certification requirements, such as for the FCC or UL.

Startup Connector will help entrepreneurs with product development and certification, finding suppliers and manufacturers, and charting a path to commercialization via investors, distributors, and customers. And its founders envision working with no more than a handful of companies that they'll guide down two different ten-week tracks:

Business Startup Track: Startup Basics (Lean Startup, Business Model Canvas), Case Studies, Market Assessments, Overview of Financing/Capital/VC Models, Intellectual Property, and Certification Programs

Design & Manufacturing Track: Product Development, Design Methodology, Engineering & Design Practices, Prototyping, Packaging Design, Supply Chain Management, Quality Assurance, and Manufacturing Introductions

In addition to providing specialized expertise, accelerator programs also typically provide seed funding for a small stake in the launched companies. Kobayashi said that he and Nakata haven't quite finalized these details for Startup Connector.

"We have discussed it, there are a couple of different models that we're trying to approach, so we're going to talk with the companies and see what makes sense," he said. "We're actively pursuing both state and federal funds."

Kobayashi said the first cohort will be limited to Hawaii-based companies. Applications for the accelerator will be accepted during the month of December, with the program kicking off in January. For more information, visit Startup-Connector.com.

Listen to the full interview with Kobayashi here:

https://archive.org/download/startup-connector-hardware-accelerator/startup-connector-hardware-accelerator.mp3

Photos courtesy Startup Connector and 3D Innovations on Facebook.